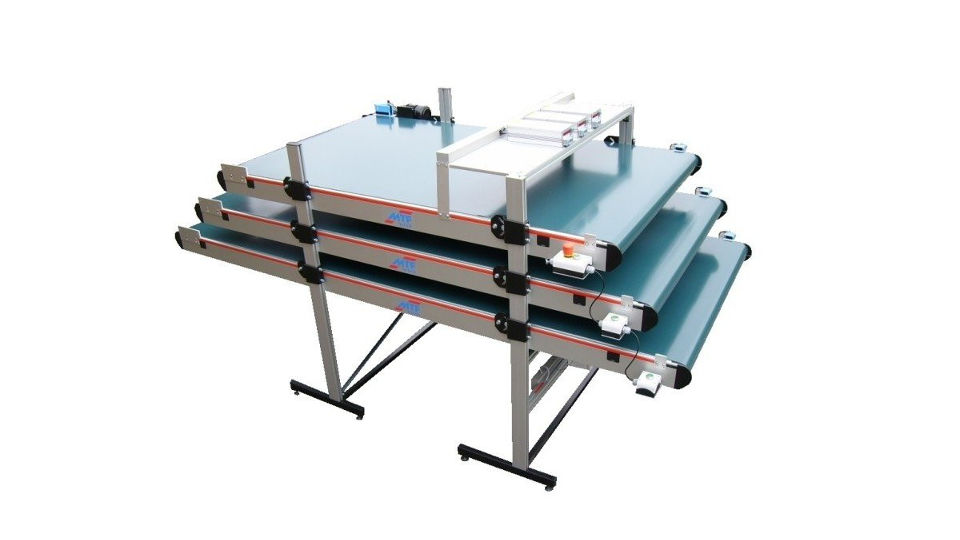

Multi-Level Conveyor for a robot cell

For the buffering of individual pieces that are deposited on conveyor belts by an outtake handling, a simple stacked belt system recommends itself as a cost-effective alternative to similar lift systems. Depending on the desired degree of complexity, different control concepts and interfaces with production machines or to the handling can be realised.

Advantages:

- Three separate small controllers (digital cycle switching devices) for the conveyors

- Belt dump buttons for manual control of piece removal

- Sensors according to customer requirements

- Interface to the parent robot controller

- Connection to emergency stop circuits

Multi-Level Conveyor Belts with Pneumatic Lifts

Efficient container management in the smallest space: The Multi-Tech Lift buffer station was developed for exactly this purpose and can be perfectly adapted to the individual conditions, thanks to its modular system. The integrated SPS control provides an automatised production run so that, for example, night shifts or weekend shifts can be run completely without personnel. Unmanned shifts or weekend use is possible in many production plants only with the appropriate buffer technology. Since the available space is often very limited, stacked belt systems with lifts offer an ideal use of space.