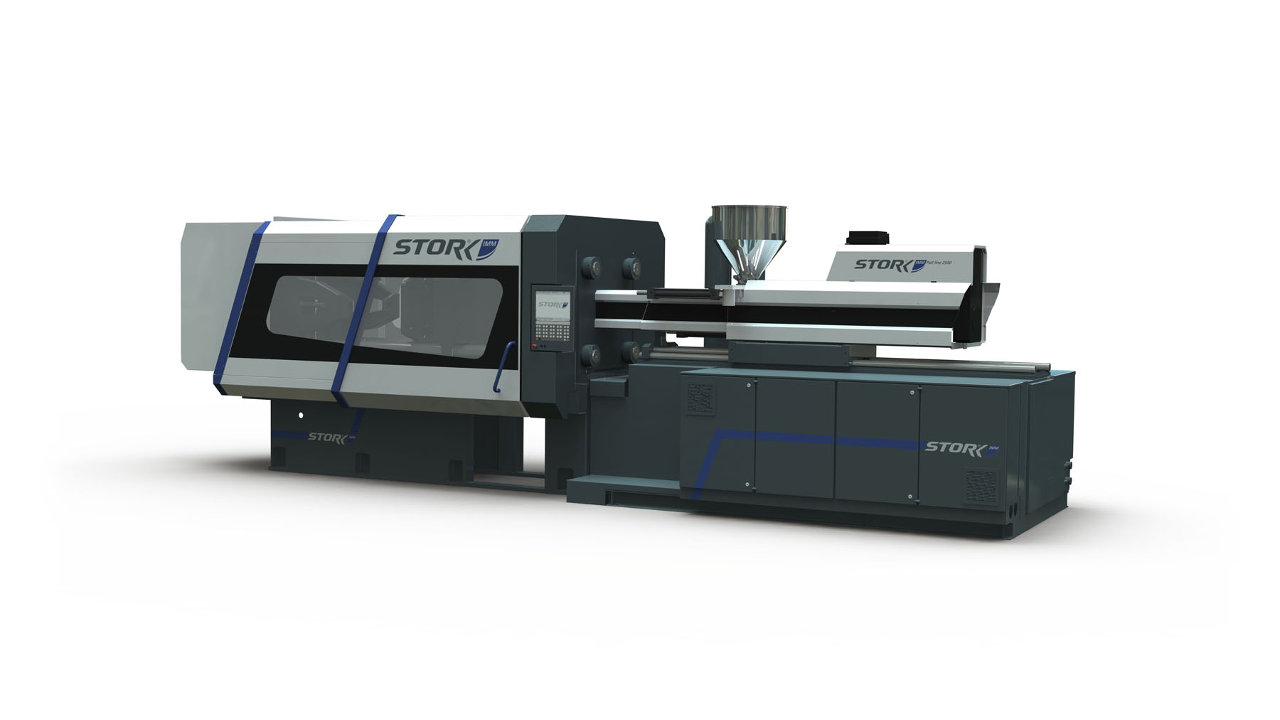

PAIL-LINE: The Stork Pail-Line represents top quality in injection moulding machines for manufacturing containers and lids.

Primary assets of the Pail-Line

The production of containers for the food-industry requires maximum hygiene. The Stork Pail-Line can also be lubricated with food-grade oil and lubricants. Stork offers a wide choice in drive systems which enables us to offer you always the fastest and most energy efficient machine. Thanks to enlarged opening-strokes, IML and take-out is possible in one movement which results in a shorter cycle-time.

Stork uses a robust toggle system. The toggle system guarantees the shortest dry-cycle time at the lowest energy consumption. Ejecting containers requires a lot of air and perfect timing. The freely programmable high-flow air—valves with separate adjustment of flow and pressure guarantees the shortest demoulding times, resulting in the shortest cycle-times. Pails are increasingly fitted with integrated handles. The 2K unit needed to facilitate this is available in different sizes and arrangements.

Clamping-unit

Fast and Smooth

- Robust 5-point toggle system guarantees fastest and smoothest movements

- Reinforced linear rail guidance provides accurate durable mould guidance

- Increased opening strokes for IML are available

- Extremely stiff platens are used for symmetrical filing and minimum clamping-force

- The extremely fast and precise mould security protects your valuable moulds

- Progressive lubrication with active monitoring ensures high reliability and long life-time

- Suitable for food-grade lubricantInternal tie-bar clamping-force measurement increases process quality

Drives

Accurate and energy efficient

- Parallel movements of all functions enables shortest cycle-times

- Hybrid accumulator drive for fastest speeds and extremely short response times

- Comes standard with Stork controlled energy-optimised fast variable pumpIn-line high pressure filtration increases reliability

- Frequency controlled main engine reduces idle losses

- Electrical clamping unit with robust rack and pinion drive and regenerative unit allows for shortest cycle-times at lowest energy consumption

- Electric injection fine-tuned for thin-walled applications

SC1301 Smart Touch

Intelligent and user-friendly

- The IPC with 19”multi-touch screen presents all information in a clear and orderly fashion

- Stork’s own software development department provides us full control over process and optimisationIn-house software development guarantees short delivery-times in software changes

- Proven user-friendly concept

- Free programmable core-pulling and air-valve sequences are easy to program

- Integrated hot-runner with graphical display and optional current monitoring, boost and follow-me-function increases process quality and controllability

- Remote service enables fast service intervention via our Stork help-desk

- The ECO page allows for energy optimisation of the process

Injection-unit

High output and homogenous melt

- Special mixing screws up to and including 27 l/d deliver highest output and optimum dispersion of master-batch

- Extremely fast injection and switch-over are ultimate conditions for quality in thin-walled injection moulding

- The robust shut-off nozzle with large bore reduces pressure-drop

- 2K-solutions in different arrangements are available for different applications

- High circumferential speeds enable short plasticizing times and high output